Armstrong all-stainless steel air/gas vent valve, including 11-AV, 22-AV, 13-AV models, excellent corrosion resistance, working pressure up to 600 psig (41 bar), adaptable to specific gravity as low as 0.50, superior sealing performance, suitable for pressure venting requirements in various corrosive environments.

Armstrong 11-AV, 22-AV, 13-AV series all-stainless steel free floating lever air/gas vent valves are designed specifically for positive air/gas venting in pressure environments. The product features an all-stainless steel construction that can handle both internal and external corrosive conditions. Its core technology originates from Armstrong's proven free floating mechanism used in steam traps, ensuring precise valve seating and reliable sealing under various operating conditions. This series of vent valves can operate at pressures up to 600 psig (41 bar), adapt to specific gravity as low as 0.50, and achieve flow rates up to 115 SCFM, making them ideal venting solutions for corrosive environments and high-pressure applications in industrial settings.

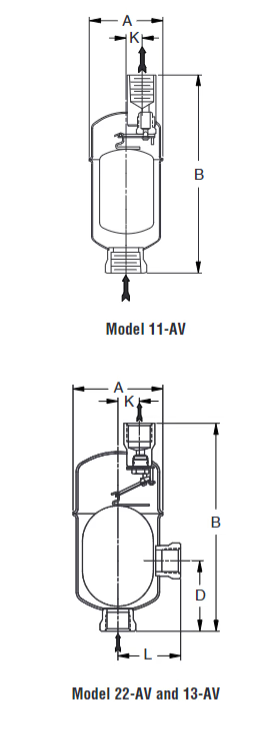

| Model | Pipe Connection Size | Dimension "A" (inch/mm) | Dimension "B" (inch/mm) | Dimension "D" (inch/mm) | Dimension "K" (inch/mm) | Weight (lb/kg) |

|---|---|---|---|---|---|---|

| 11-AV | 1/2, 3/4 inch (15mm outlet) | 2-3/4 / 70 | 7-1/4 / 184 | - / - | 9/16 / 14 | - |

| 22-AV | 1/2, 3/4 inch | 3-7/8 / 99 | 8-13/16 / 224 | 3-3/8 / 86 | 7/8 / 22 | 5 / 2.3 |

| 13-AV | 1/2, 3/4 inch | 4-1/2 / 114 | 11-3/8 / 289 | 6-1/8 / 156 | 1-3/16 / 30 | 7-1/2 / 3.4 |

| Model | 100°F (38°C) | 500°F (260°C) |

|---|---|---|

| 11-AV | 500 psig (34 bar) | 440 psig (30 bar) |

| 22-AV | 600 psig (41 bar) | 475 psig (33 bar) |

| 13-AV | 570 psig (39 bar) | 490 psig (34 bar) |

| Float Ball Weight (oz/g) | Orifice Size (inch) | Specific Gravity 0.75 (psi/bar) | Specific Gravity 0.50 (psi/bar) |

|---|---|---|---|

| Standard 2.90 (82) | 1/8 | 178 / 12 | 118 / 8 |

| Standard 2.90 (82) | #38 | 267 / 18 | 177 / 12 |

| Standard 2.90 (82) | 5/64 | 400 / 28 | 311 / 21 |

| Special 2.08 (59) | 1/8 | - / - | 118 / 8 |

| Special 2.08 (59) | #38 | - / - | 177 / 12 |

| Special 2.08 (59) | 5/64 | - / - | 311 / 21 |

| Float Ball Weight (oz/g) | Orifice Size (inch) | SG 1.00 (psi/bar) | SG 0.95 (psi/bar) | SG 0.90 (psi/bar) | SG 0.85 (psi/bar) | SG 0.80 (psi/bar) | SG 0.75 (psi/bar) | SG 0.70 (psi/bar) | SG 0.65 (psi/bar) | SG 0.60 (psi/bar) | SG 0.55 (psi/bar) | SG 0.50 (psi/bar) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10.0 (282) | 5/16 | 35 / 2.4 | 33 / 2.3 | 31 / 2.2 | 30 / 2.0 | 28 / 1.9 | 26 / 1.8 | 19 / 1.3 | 18 / 1.2 | 16 / 1.1 | 15 / 1.0 | 14 / 0.9 |

| 10.0 (282) | 1/4 | 57 / 3.9 | 54 / 3.7 | 51 / 3.5 | 49 / 3.4 | 46 / 3.2 | 43 / 3.0 | 31 / 2.1 | 29 / 2.0 | 27 / 1.8 | 24 / 1.7 | 22 / 1.5 |

| 10.0 (282) | 3/16 | 126 / 8.7 | 120 / 8.2 | 113 / 7.8 | 107 / 7.4 | 101 / 7.0 | 95 / 6.5 | 68 / 4.7 | 64 / 4.4 | 59 / 4.1 | 54 / 3.7 | 49 / 3.4 |

| 10.0 (282) | 5/32 | 217 / 14.9 | 206 / 14.2 | 195 / 13.5 | 185 / 12.7 | 174 / 12.0 | 163 / 11.2 | 118 / 8.1 | 110 / 7.6 | 101 / 7.0 | 93 / 6.4 | 85 / 5.8 |

| 10.0 (282) | 1/8 | 371 / 25.6 | 352 / 24.3 | 334 / 23.0 | 316 / 21.8 | 297 / 20.5 | 279 / 19.2 | 202 / 13.9 | 187 / 12.9 | 173 / 12.0 | 159 / 11.0 | 145 / 10.0 |

| 10.0 (282) | 7/64 | 474 / 32.7 | 451 / 31.1 | 427 / 29.5 | 404 / 27.9 | 380 / 26.2 | 357 / 24.6 | 258 / 17.8 | 240 / 16.5 | 222 / 15.3 | 204 / 14.0 | 186 / 12.8 |

| 10.0 (282) | #38 | 590 / 40.7 | 561 / 38.7 | 532 / 36.7 | 503 / 34.7 | 473 / 32.7 | 444 / 30.6 | 321 / 22.1 | 298 / 20.6 | 276 / 19.0 | 253 / 17.5 | 231 / 15.9 |

| 10.0 (282) | 5/64 | 600 / 41.4 | 600 / 41.4 | 600 / 41.4 | 600 / 41.4 | 600 / 41.4 | 600 / 41.4 | 473 / 32.6 | 440 / 30.3 | 407 / 28.1 | 374 / 25.8 | 341 / 23.5 |

| Float Ball Weight (oz/g) | Orifice Size (inch) | SG 1.00 (psi/bar) | SG 0.95 (psi/bar) | SG 0.90 (psi/bar) | SG 0.85 (psi/bar) | SG 0.80 (psi/bar) | SG 0.75 (psi/bar) | SG 0.70 (psi/bar) | SG 0.65 (psi/bar) | SG 0.60 (psi/bar) |

|---|---|---|---|---|---|---|---|---|---|---|

| 14.9 (423) | 1/2 | 21 / 1.5 | 20 / 1.4 | 19 / 1.3 | 18 / 1.3 | 17 / 1.2 | 16 / 1.1 | 15 / 1.0 | 14 / 1.0 | 13 / 0.9 |

| 14.9 (423) | 3/8 | 45 / 3.1 | 43 / 3.0 | 41 / 2.8 | 38 / 2.7 | 36 / 2.5 | 34 / 2.3 | 32 / 2.2 | 30 / 2.0 | 27 / 1.9 |

| 14.9 (423) | 5/16 | 72 / 5.0 | 69 / 4.7 | 65 / 4.5 | 61 / 4.2 | 58 / 4.0 | 54 / 3.8 | 51 / 3.5 | 47 / 3.3 | 44 / 3.0 |

| 14.9 (423) | 9/32 | 96 / 6.6 | 91 / 6.3 | 87 / 6.0 | 82 / 5.6 | 77 / 5.3 | 72 / 5.0 | 68 / 4.7 | 63 / 4.3 | 58 / 4.0 |

| 14.9 (423) | 1/4 | 144 / 9.9 | 137 / 9.4 | 130 / 8.9 | 123 / 8.5 | 116 / 8.0 | 109 / 7.5 | 102 / 7.0 | 94 / 6.5 | 87 / 6.0 |

| 14.9 (423) | 7/32 | 206 / 14 | 196 / 13 | 186 / 13 | 176 / 12 | 165 / 11 | 155 / 10.7 | 145 / 10.0 | 135 / 9.3 | 125 / 8.6 |

| 14.9 (423) | 3/16 | 309 / 21 | 294 / 20 | 279 / 19 | 264 / 18 | 249 / 17 | 234 / 16 | 218 / 15 | 203 / 14 | 188 / 13 |

| 14.9 (423) | 5/32 | 484 / 33 | 460 / 32 | 437 / 30 | 413 / 28 | 389 / 27 | 365 / 25 | 342 / 24 | 318 / 22 | 294 / 20 |

| 14.9 (423) | 1/8 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 |

| 14.9 (423) | 7/64 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 | 570 / 39 |

Note: If the actual specific gravity falls between the values in the table, use the parameters corresponding to the next lower specific gravity (e.g., if the actual specific gravity is 0.73, refer to the 0.70 specific gravity data).

| Model | Weight (lb) | Weight (kg) |

|---|---|---|

| 11-AV | - | - |

| 22-AV | 5 | 2.3 |

| 13-AV | 7-1/2 | 3.4 |

| Model | Valve and Seat | Lever System | Float Ball | Body and Cover |

|---|---|---|---|---|

| 11-AV | Hardened Chrome Steel-17-4PH (316 stainless steel optional, consult manufacturer) | - | 304 Stainless Steel | 304-L Sealed Stainless Steel |

| 22-AV | 303/304 Stainless Steel (316 stainless steel optional, consult manufacturer) | Stainless Steel | - | 304-L Sealed Stainless Steel |

| 13-AV | 316 Stainless Steel optional (consult manufacturer) | Stainless Steel | - | 304-L Sealed Stainless Steel |

Explore similar products in our catalog