Product Overview

BURKERT 5281 is a servo diaphragm 2/2-way solenoid valve designed specifically for precise control of liquid or gas media. The product features an innovative construction that requires only one solenoid coil to adapt to all port size specifications, combining core advantages of water hammer-free operation and low noise, with short installation length and support for both threaded and flanged connection methods. Some models offer optional manual operation function, adapting to diverse installation requirements in industrial scenarios.

Key Features

- Easy Operation: Single solenoid coil adapts to the entire series of port sizes, simplifying selection and maintenance procedures.

- Stable Operation: Water hammer-free design reduces pipeline impact, low noise operation improves workplace comfort.

- Flexible Adaptation: Supports NC (normally closed) / NO (normally open) switching functions, optional NBR, EPDM, FKM seal materials, covering various media scenarios.

- Flexible Installation: Can be installed in any direction, recommended actuator upward installation for optimal performance; threaded and flanged versions meet different pipeline connection needs.

- Reliable Protection: IP65 protection rating, suitable for harsh industrial environments, ensuring long-term stable operation.

Technical Parameter Details

Basic Parameters

| Parameter Category | Details |

|---|

| Valve type | 2/2-way servo diaphragm solenoid valve |

| Switching function | NC (normally closed), NO (normally open) |

| Nominal diameter (DN) | 13 mm, 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 65 mm |

| Port size | Threaded: G 1/2, G 3/4, G 1, G 1 1/4, G 1 1/2, G 2, G 2 1/2; Flanged: DIN 2501 |

| Pressure range | 0.2 - 16 bar (0.5 bar differential pressure required for complete switching) |

| Voltage specifications | 24V DC, 24V 50-60Hz, 230V 50-60Hz, 110V 50Hz (non-standard voltages can be customized) |

| Operating mode | 100% continuous duty (ED) |

| Response time | 0.1 - 4 seconds (at 6 bar, +20°C conditions, opening: pressure from 0 to 90%; closing: pressure from 100% to 10%) |

Temperature Parameters

| Seal Material | Media Temperature Range | Special Notes |

|---|

| NBR | -10 to +80 °C | - |

| EPDM | -40 to +90 °C | Epoxy coil version up to +100 °C |

| FKM | -10 to +90 °C | Epoxy coil version up to +120 °C |

| - | Ambient temperature | Maximum +55 °C |

| Seal Material | Applicable Media |

|---|

| NBR | Neutral media, such as compressed air, water, etc. |

| EPDM | Oil-free and grease-free media |

| FKM | Hot air, aggressive solutions, etc. |

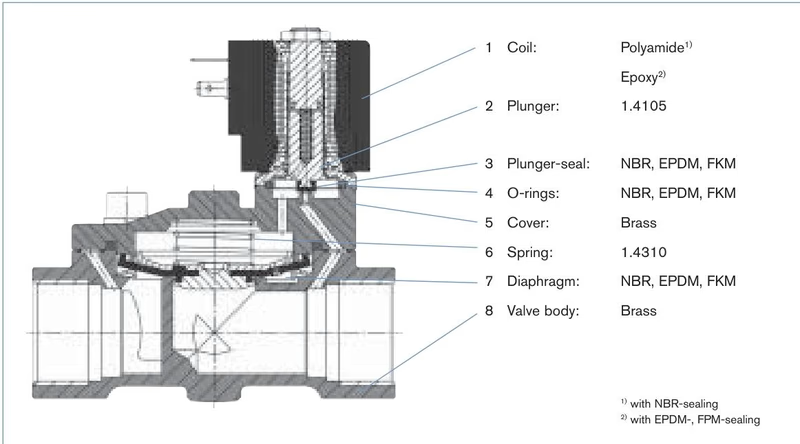

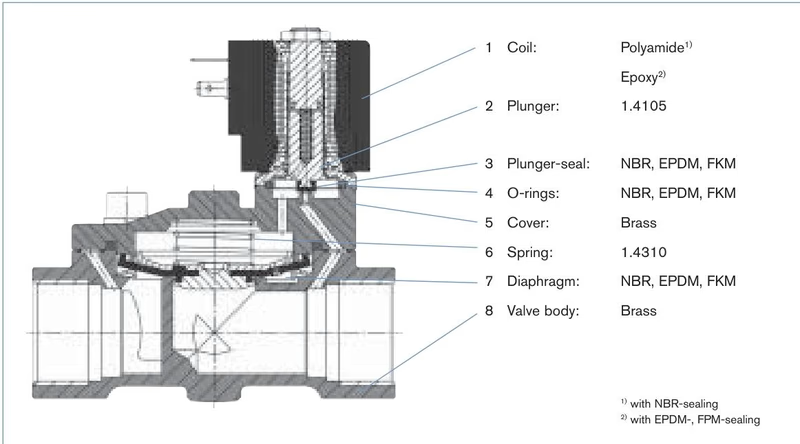

Component Material Details

| Component No. | Component Name | Material Specification | Notes |

|---|

| 1 | Coil | Polyamide (for NBR seal), Epoxy (for EPDM/FKM seal) | - |

| 2 | Plunger | 1.4105 Stainless steel | - |

| 3 | Plunger seal | NBR, EPDM, FKM | Same as valve seal material |

| 4 | O-ring | NBR, EPDM, FKM | Same as valve seal material |

| 5 | End cover | Brass | - |

| 6 | Spring | 1.4310 Stainless steel | - |

| 7 | Diaphragm | NBR, EPDM, FKM | Same as valve seal material |

| 8 | Body | Brass (threaded port), Cast iron (flanged port) | Threaded port complies with DIN EN 50930-6 standard |

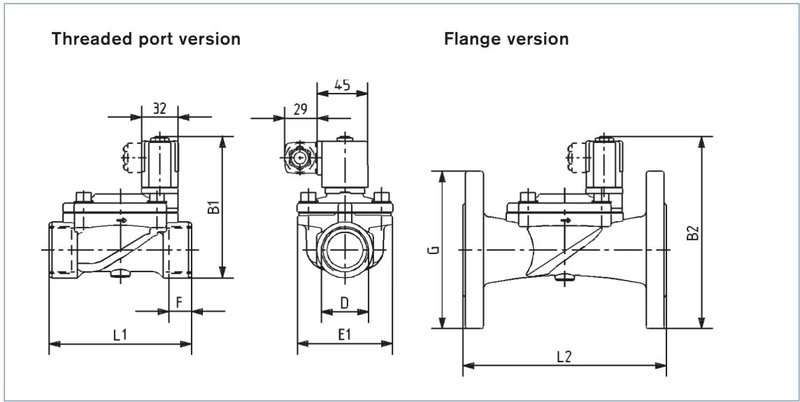

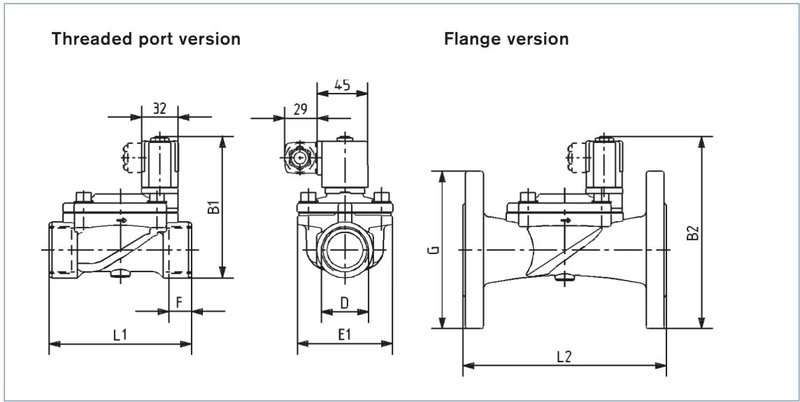

Dimensions

Threaded Port Version (Unit: mm)

| DN | Port Size | B1 (Circuit Function A) | B1 (Circuit Function B) | B1* (With Manual Operation) | E1 | F | L1 |

|---|

| 13 | G 1/2 | 100.0 | 102.0 | - | 110 | 40 | 14 |

| 20 | G 3/4 | 107.5 | 109.5 | - | 117.5 | 60 | 16 |

| 25 | G 1 | 116.0 | 118.0 | 159.5 | 126.0 | 70 | 18 |

| 32 | G 1 1/4 | 126.5 | 128.5 | 171.5 | 136.5 | 85 | 20 |

| 40 | G 1 1/2 | 135.5 | 137.5 | 180.5 | 145.5 | 85 | 22 |

| 50 | G 2 | 157.2 | 159.2 | 204.7 | 167.2 | 115 | 24 |

| 65 | G 2 1/2 | 157.2 | 159.2 | - | 167.2 | 115 | 27 |

Flanged Port Version (Unit: mm)

| DN | Port Size | B2 (Circuit Function A) | B2* (With Manual Operation) | G | L2 |

|---|

| 25 | DIN 2501 | 115 | 169.5 | 120 | 160 |

| 32 | DIN 2501 | 126 | 181.5 | 140 | 180 |

| 40 | DIN 2501 | 126 | 190.5 | 150 | 200 |

| 50 | DIN 2501 | 164 | 214.7 | 165 | 230 |

Note: The total height B1 for circuit function B is 2 mm higher than circuit function A; versions with manual operation are marked as B1*, B2*.

Threaded Port (Brass Body, Without Cable Plug)

| Circuit Function | Seal Material | Port Size | DN (mm) | Kv Value (m³/h) | 24V DC Model | 24V 50-60Hz Model | 230V 50-60Hz Model |

|---|

| NC (A) | NBR | G 1/2 | 13 | 4.0 | 134 317 | 134 318 | 134 320 |

| NC (A) | NBR | G 3/4 | 20 | 6.4 | 134 321 | 134 322 | 134 324 |

| NC (A) | NBR | G 1 | 25 | 10.0 | 134 325 | 134 326 | 134 328 |

| NC (A) | EPDM | G 1/2 | 13 | 4.0 | 134 373 | 134 374 | 134 376 |

| NC (A) | FKM | G 1/2 | 13 | 4.0 | 134 345 | 134 346 | 134 348 |

| NO (B) | NBR | G 1/2 | 13 | 4.0 | 178 873 | 178 872 | 178 874 |

| NO (B) | NBR | G 3/4 | 20 | 6.4 | 178 876 | 178 875 | 178 877 |

With Manual Operation (Threaded Port, Brass Body, Without Cable Plug)

| Circuit Function | Seal Material | Port Size | DN (mm) | Kv Value (m³/h) | 24V DC Model | 24V 50-60Hz Model | 230V 50-60Hz Model |

|---|

| NC (A) | NBR | G 1/2 | 13 | 4.0 | 139 307 | 139 308 | 138 314 |

| NC (A) | NBR | G 3/4 | 20 | 6.4 | 139 309 | 139 310 | 139 311 |

| NC (A) | NBR | G 1 | 25 | 10.0 | 139 312 | 139 313 | 138 801 |

Flanged Port (Cast Iron Body, Without Cable Plug)

| Circuit Function | Seal Material | Port Size | DN (mm) | Kv Value (m³/h) | 24V DC Model | 24V 50-60Hz Model | 230V 50-60Hz Model |

|---|

| NC (A) | NBR | DIN 2501 | 25 | 10.0 | 134 401 | 134 402 | 134 404 |

| NC (A) | NBR | DIN 2501 | 32 | 20.0 | 134 405 | 134 406 | 134 408 |

| NC (A) | NBR | DIN 2501 | 50 | 40.0 | 134 413 | 134 414 | 134 416 |

| Spare Part Name | Model/Specification | Compatible Products | Included Components |

|---|

| Cable plug | Type 2508 | Type 5281 full series | Flat washer, fixing screws |

| Fixing screws | Standard accessory | Type 2508 cable plug | Supplied with cable plug |

| Flat washer | Standard accessory | Type 2508 cable plug | Supplied with cable plug |

Note: Cable plug must be ordered separately. For other non-standard cable plug versions (complying with DIN EN 175301-803 Form A), please refer to Type 2508 separate data sheet.

Certifications and Compliance

The product has passed UL/UR/CSA certification, UL fire safety certification and European gas certification, complying with industrial safety and environmental standards, suitable for use in various industrial scenarios.

Installation and Usage Recommendations

- Installation direction can be chosen arbitrarily, actuator upward installation is recommended to ensure optimal performance.

- Ensure media compatibility with the selected seal material to avoid leakage or damage due to material mismatch.

- Electrical connection must use Type 2508 cable plug to ensure protection rating compliance.

- Working pressure must meet 0.2 - 16 bar range, complete switching requires 0.5 bar differential pressure.

- Special application scenarios (such as non-standard voltage, NPT/Rc ports) can contact the manufacturer for customization.