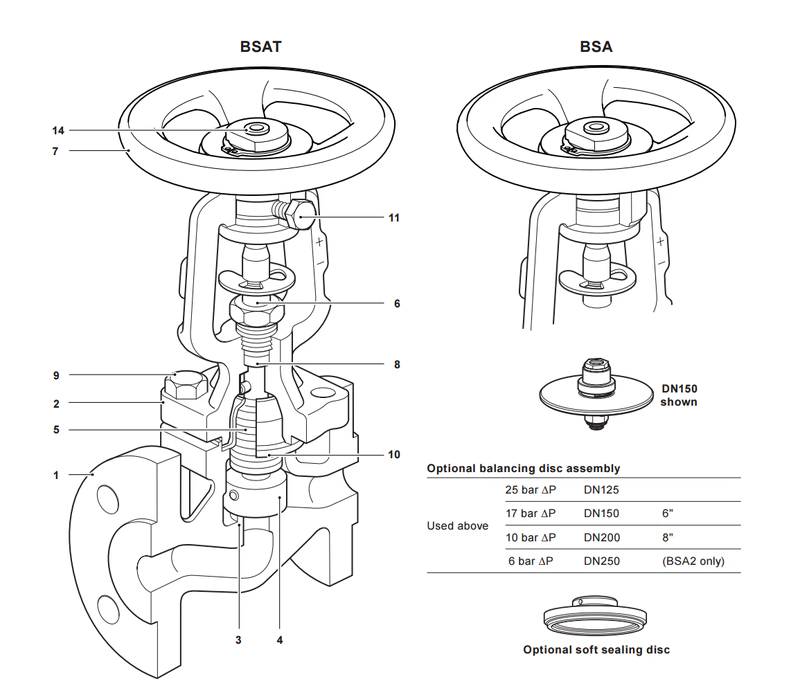

Spirax Sarco BSA/BSAT series bellows sealed globe valves, including BSA (flat disc) and BSAT (throttling disc + stem locking device) series, suitable for steam, gas, liquid, condensate and water systems. Features double bellows seal design, compliant with European Pressure Equipment Directive 97/23/EC, sealing class EN 12266-1 Class A and ISO 5208 Class A, available in ductile iron and cast steel materials for reliable sealing and stable operation.

Spirax Sarco BSA and BSAT series are bellows sealed globe valves featuring double bellows seal design, suitable for steam, gas, liquid, condensate and water systems. The standard BSAT series is equipped with throttling disc and stem locking device, while the optional BSA series features flat disc design with optional balanced disc configuration. Products comply with European Pressure Equipment Directive 97/23/EC, and EN 10204 3.1 certificates are available for certain models (BSA2, BSA2T, BSA3, BSA3T) upon request at time of order.

| Material | Model | Connection Type | Size Range (DN) | Options |

|---|---|---|---|---|

| Ductile Iron | BSA2T | PN16, PN25, PN40 | 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200 | R-PTFE Soft Seat |

| Cast Steel | BSA3T | ANSI 150, ANSI 300, KS 20 | 15, 20, 25, 40, 50, 80, 100, 150, 200 | R-PTFE Soft Seat |

| Material | Model | Connection Type | Size Range (DN) | Options |

|---|---|---|---|---|

| Ductile Iron | BSA2 | PN16, PN25 | 125, 150, 200 | Balanced Disc |

| Cast Steel | BSA3 | PN40, ANSI 150, ANSI 300, KS 20 | 125, 150, 200 | Balanced Disc |

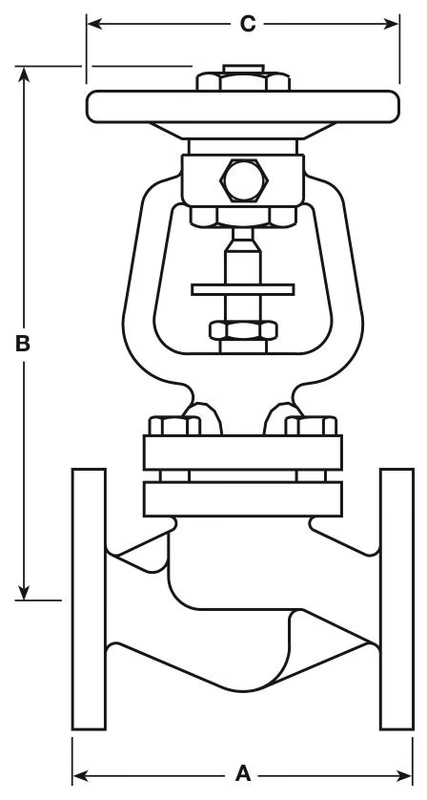

| Size | A(PN) | A(JIS/KS 10K) | A(JIS/KS 20K) | A(ANSI 150) | A(ANSI 300) | B | C | Weight(BSA2 BSA2T) | Weight(BSA3 DIN) | Weight(BSA3 ANSI 150) | Weight(BSA3 ANSI 300 JIS/KS 20K) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN15 | 130 | 133 | 152 | 108 | 152 | 205 | 125 | 4 | 4 | 5 | 6 |

| DN20 | 150 | 153 | 178 | 117 | 178 | 205 | 125 | 4 | 5 | 6 | 7 |

| DN25 | 160 | 163 | 200 | 127 | 203 | 217 | 125 | 5 | 6 | 8 | 9 |

| DN32 | 180 | 183 | - | - | - | 217 | 125 | 7 | 8 | - | - |

| DN40 | 200 | 203 | 224 | 165 | 229 | 243 | 200 | 10 | 11 | 10 | 11 |

| DN50 | 230 | 229 | 259 | 203 | 267 | 243 | 200 | 12 | 14 | 12 | 15 |

| DN65 | 290 | 293 | - | - | - | 263 | 200 | 16 | 19 | - | - |

| DN80 | 310 | 309 | 304 | 241 | 317 | 287 | 200 | 21 | 26 | 25 | 29 |

| DN100 | 350 | 349 | 340 | 292 | 356 | 383 | 315 | 36 | 44 | 41 | 49 |

| DN125 | 400 | 395 | - | - | - | 416 | 315 | 52 | 64 | - | - |

| DN150 | 480 | 479 | 428 | - | 445 | 450 | 315 | 75 | 88 | - | 94 |

| DN200 | 600 | 592 | 537 | - | 559 | 622 | 500 | 145 | - | - | 193 |

| Size (DN) | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Kv Value | 4 | 7 | 12 | 19 | 30 | 47 | 77 | 120 | 193 | 288 | 410 | 725 | 1145 |

| Size Range | Max Pressure Differential (bar) |

|---|---|

| DN15-DN80 | 2.0 |

| DN100-DN125 | 1.5 |

| DN150 | 1.0 |

| DN200-DN250 | 0.8 |

Note: When BSAT is used for throttling, exceeding the above pressure differential will increase noise and vibration

| No. | Component | BSA2 / BSA2T | BSA3 / BSA3T (DIN) | BSA3 / BSA3T (ANSI) |

|---|---|---|---|---|

| 1 | Body | Ductile Iron EN-GJS-400-18-LT | Cast Steel 1.0619 (GSC 25N) | Cast Steel ASTM A 216 WCB |

| 2 | Bonnet | Ductile Iron EN-GJS-400-18-LT | Steel (DN15-DN80) DIN 17243 C 22.8; Steel (DN100-DN200) 1.0619 | Forged Steel (DN15-DN80) ASTM A 105; Cast Steel (DN100-DN200) ASTM A 216 WCB |

| 3 | Seat | Stainless Steel AISI 420 | Stainless Steel AISI 420 | Stainless Steel AISI 420 |

| 3-1 | Metal Seat Disc | Stainless Steel DIN 17440 X30 Cr13 | Stainless Steel DIN 17440 X30 Cr13 | Stainless Steel DIN 17440 X30 Cr13 |

| 4 | Soft Seat Disc | Stainless Steel DIN 17440 X30 Cr13 | Stainless Steel DIN 17440 X30 Cr13 | Stainless Steel DIN 17440 X30 Cr13 |

| 4-1 | Soft Seat Insert | R-PTFE 25% Carbon Filled | R-PTFE 25% Carbon Filled | R-PTFE 25% Carbon Filled |

| 5 | Bellows | Stainless Steel DIN 17440 X6 Cr Ni Ti 1810 | Stainless Steel DIN 17440 X6 Cr Ni Ti 1810 | Stainless Steel DIN 17440 X6 Cr Ni Ti 1810 |

| 6 | Stem | Stainless Steel AISI 420 | Stainless Steel AISI 420 | Stainless Steel AISI 420 |

| 7 | Handwheel | Pressed Steel BS 1449 CR4 | Pressed Steel BS 1449 CR4 | Pressed Steel BS 1449 CR4 |

| 8 | Stem Packing | Graphite | Graphite | Graphite |

| 9 | Bonnet Stud | Steel DIN 17420 24 Cr Mo 5 | Steel DIN 17420 24 Cr Mo 5 | Steel ASTM A 193 B7 |

| 9-1 | Bonnet Nut | Steel DIN 17420 Ck 5 | Steel DIN 17420 Ck 5 | Steel ASTM A 192 2 H |

| 10 | Body/Bonnet Gasket | Stainless Steel Reinforced Laminated Graphite | Stainless Steel Reinforced Laminated Graphite | Stainless Steel Reinforced Laminated Graphite |

| 11 | Lock Nut | DN15-DN80: Steel M8×14mm BS 3692 Gr.8.8; DN100-DN150: Steel M8×20mm; DN200-DN250: Steel M12×20mm | DN15-DN80: Steel M8×14mm BS 3692 Gr.8.8; DN100-DN150: Steel M8×20mm; DN200-DN250: Steel M12×20mm | DN15-DN80: Steel M8×14mm BS 3692 Gr.8.8; DN100-DN150: Steel M8×20mm; DN200-DN250: Steel M12×20mm |

| Size Range (DN) | Required Hex Bolt Specification |

|---|---|

| 15-80 | M8×50mm |

| 100-150 | M12×75mm |

| 200-250 | M12×100mm |

Note: Stroke limiter requires customer-supplied standard bolts and nuts; handwheel nut has pre-threaded mounting hole

| Size (DN) | Applicable Pressure Differential (bar) |

|---|---|

| 125 | >25 |

| 150 | >17 |

| 200 | >10 |

| 250 (BSA2 only) | >6 |

| Design Parameter | PN16 | JIS/KS 10K | PN25 | JIS/KS 20K |

|---|---|---|---|---|

| Maximum Allowable Pressure (PMA) | 16 bar g | 16 bar g | 25 bar g | 25 bar g |

| Maximum Allowable Temperature (TMA) | 350°C | 350°C | 350°C | 350°C |

| Max Operating Pressure - Saturated Steam (PMO) | 14.7 bar g | 14.7 bar g | 22.3 bar g | 22.3 bar g |

| Max Operating Temperature (TMO) - Soft Seat | 230°C | 230°C | 230°C | 230°C |

| Max Operating Temperature (TMO) - Metal Seat | 350°C | 350°C | 350°C | 350°C |

| Minimum Operating Temperature | -10°C | -10°C | -10°C | -10°C |

| Design Max Cold Hydrostatic Test Pressure | 24 bar g | 24 bar g | 38 bar g | 38 bar g |

| Design Parameter | ANSI 150 | ANSI 300 | JIS/KS 20K |

|---|---|---|---|

| Maximum Allowable Pressure (PMA) | 19.6 bar g | 51 bar g | 34 bar g |

| Maximum Allowable Temperature (TMA) | 425°C | 425°C | 425°C |

| Max Operating Pressure - Saturated Steam (PMO) | 14 bar g | 41.6 bar g | 30.7 bar g |

| Max Operating Temperature (TMO) - Soft Seat | 230°C | 230°C | 230°C |

| Max Operating Temperature (TMO) - Metal Seat | 425°C | 425°C | 425°C |

| Minimum Operating Temperature | -29°C | -29°C | 0°C |

| Design Max Cold Hydrostatic Test Pressure | 31 bar g | 77 bar g | 50 bar g |

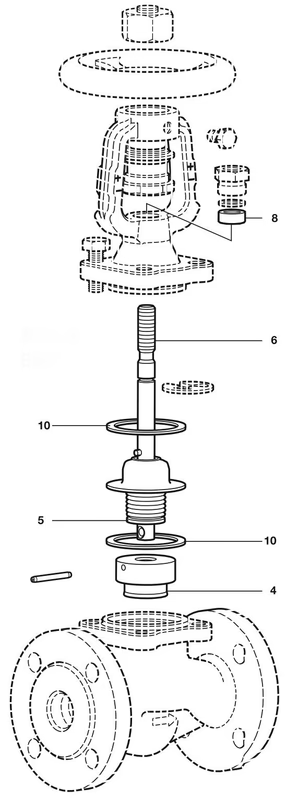

| Spare Part Name | Included Component Numbers |

|---|---|

| Body/Bonnet Gasket and Stem Packing | 10, 8 (2 sets) |

| Stem and Bellows Assembly (specify BSA/BSAT) | 5, 6, 8, 10 |

| Disc and Other Options (specify valve model) | 4, 8, 10 |

Explore similar products in our catalog