Spirax Sarco S13 ductile iron separator with flanged connection, designed for separating liquid droplets from steam, compressed air or gas systems. Features insulation jacket compatibility for enhanced performance, complies with European Pressure Equipment Directive 97/23/EC, available in DN40-DN200 sizes, operating temperature range -10°C to 350°C, widely used in industrial fluid systems for gas-liquid separation.

Spirax Sarco S13 is a baffle type separator designed to separate liquid droplets from steam, compressed air or gas systems, ensuring system operating efficiency. The product can be used with an insulation jacket to further enhance performance, suitable for various industrial fluid systems requiring gas-liquid separation. This product complies with European Pressure Equipment Directive 97/23/EC, with official test reports available for quality and safety assurance.

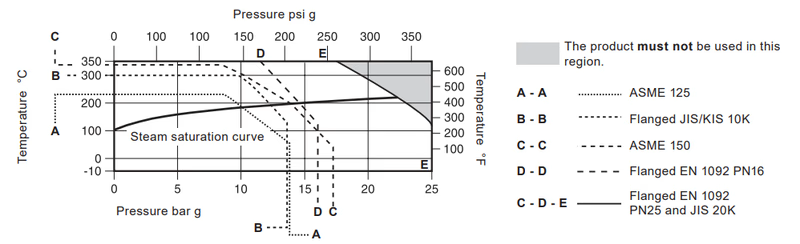

| Parameter | Flange Standard | Value |

|---|---|---|

| Body Design | - | PN25 |

| PMA Maximum Allowable Pressure | - | 25 bar g @ 100°C |

| TMA Maximum Allowable Temperature | - | 350°C @ 14 bar g |

| Minimum Allowable Temperature | - | -10°C |

| PMO Maximum Operating Pressure | JIS/KS 10K | 12.3 bar g |

| PMO Maximum Operating Pressure | PN16 | 13.7 bar g |

| PMO Maximum Operating Pressure | PN25 and JIS/KS 20K | 21.3 bar g |

| TMO Maximum Operating Temperature | - | 350°C @ 14 bar g |

| Minimum Operating Temperature | - | -10°C |

| Design Maximum Cold Hydraulic Test Pressure | JIS/KS 10K | 20.4 bar g |

| Design Maximum Cold Hydraulic Test Pressure | PN16 | 24 bar g |

| Design Maximum Cold Hydraulic Test Pressure | PN25 and JIS/KS 20K | 37.5 bar g |

Note

For lower operating temperatures, please consult Spirax Sarco.

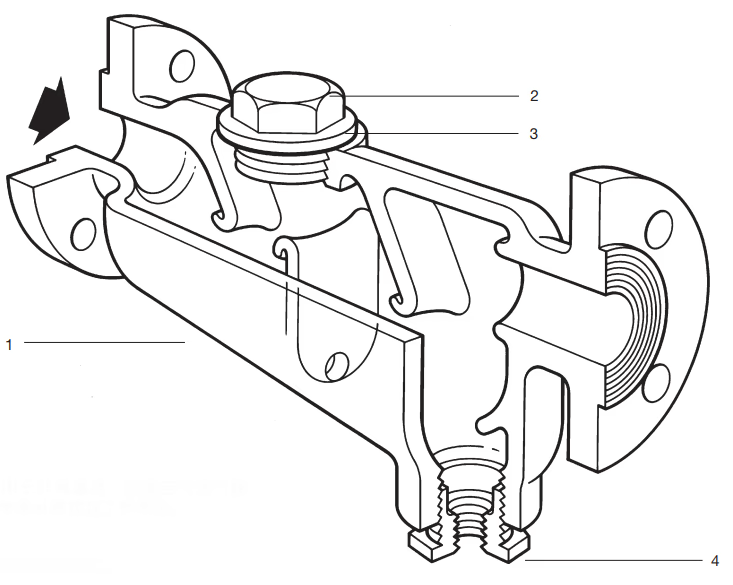

| No. | Component | Material | Standard |

|---|---|---|---|

| 1 | Body | Ductile iron | DIN 1693 GGG40, ASTM A395 |

| 2 | Plug | Carbon steel | 1.0460 (C22.8) |

| 3 | Gasket | Reinforced graphite sheet | - |

| 4 | Drain reducing bush | Forged carbon steel | ASTM A105 |

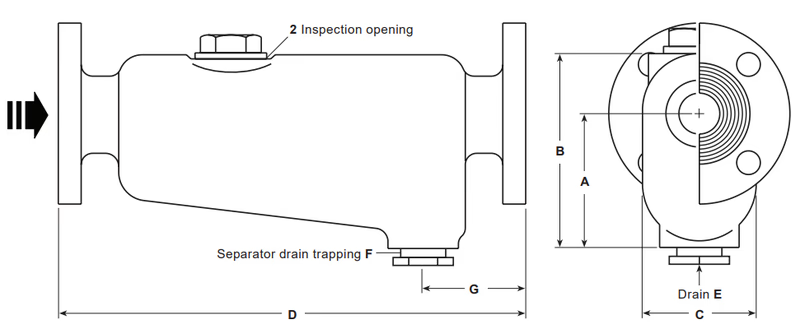

| Size | A | B | C | D | E | F | G | Weight | Capacity |

|---|---|---|---|---|---|---|---|---|---|

| DN40 | 111 | 156 | 89 | 365 | ½" | 1" | 94 | 14 kg | 1.6 L |

| DN50 | 146 | 205 | 117 | 456 | ½" | 1" | 98 | 25 kg | 3.2 L |

| DN65 | 178 | 249 | 146 | 406 | ¾" | 1½" | 98 | 28 kg | 4.6 L |

| DN80 | 178 | 252 | 152 | 483 | 1" | 1½" | 98 | 36 kg | 6.5 L |

| DN100 | 223 | 315 | 197 | 692 | 1" | 1½" | 118 | 60 kg | 13.5 L |

| DN125 | 226 | 397 | 381 | 706 | 1" | 1½" | 121 | 128 kg | 38.5 L |

| DN150 | 226 | 397 | 381 | 706 | 1" | 1½" | 121 | 130 kg | 42.5 L |

| DN200 | 308 | 502 | 426 | 762 | 1½" | 1½" | 140 | 190 kg | 68.0 L |

Note

Dimensions in mm, weight in kg, capacity in liters.

Caution

The drain outlet must be connected to a steam trap to ensure timely discharge of separated liquid, otherwise separation efficiency will be affected.

| Part | Size | Specification | Thread | Torque (N·m) |

|---|---|---|---|---|

| 2 | DN40 | 46 A/F | M56 | 150 - 165 |

| 2 | DN50 | 46 A/F | M56 | 150 - 165 |

| 2 | DN65 | 46 A/F | M56 | 150 - 165 |

| 2 | DN80 | 60 A/F | M72 | 190 - 210 |

| 2 | DN100 | 60 A/F | M72 | 190 - 210 |

| 2 | DN125 | 60 A/F | M72 | 190 - 210 |

| 2 | DN150 | 60 A/F | M72 | 190 - 210 |

| 2 | DN200 | 60 A/F | M72 | 190 - 210 |

Please specify the following information when ordering:

1-Spirax Sarco DN50 S13 Separator, ductile iron, flanged connection EN 1092 PN16

The materials used in this product are recyclable. When disposed of properly in accordance with environmental regulations, they pose no environmental hazard. Waste should be sorted for recycling and not disposed of indiscriminately.

Explore similar products in our catalog