Spirax Sarco SV60 safety valves comply with PED, EN10204 and other international standards, covering SV604 and SV607 models, suitable for steam, gases and liquids, featuring stable pressure control, wide temperature range adaptation, reliable construction and excellent discharge performance, meeting industrial safety protection requirements.

Spirax Sarco SV60 safety valves are industrial-grade safety protection equipment designed specifically for pressure control of steam, gas and liquid media. The products are certified by UKAS (Cert.No. LRQ 0963008) and comply with multiple international standards, featuring stable construction, accurate discharge performance and a wide operating temperature range, effectively preventing system overpressure and ensuring industrial production safety. The product range includes two main series, SV604 and SV607, offering various combinations of port sizes, pressure ratings and materials to meet the application requirements of different industrial scenarios.

| Parameter Item | Value |

|---|---|

| Set pressure range | Minimum 0.2 bar g, maximum 40 bar g (varies by model and size) |

| Temperature range | -10°C ~ 400°C |

| Overpressure | Steam and gases: 5%; liquids: 25% |

| Blowdown | Designed for steam, gases and liquids (designed according to corresponding standards) |

| Approvals and standards | EN10204 2.2, EN10204 3.1, PED 97/23/EC 4.2, ANSI/API STD 527-1992, LR TA96-01/00125, EN 1092-1:2002 |

| Model | Pressure Rating | Inlet Size (DN) | Outlet Size (DN) | Throat Diameter (mm) | Flow Area (mm²) |

|---|---|---|---|---|---|

| SV604 | PN40 | 20, 25, 32, 40, 50, 65, 80, 100, 125, 150 | 32, 40, 50, 65, 80, 100, 125, 150, 200, 250 | 17.0~125 | 230~12272 |

| SV607 | PN16/PN25 | 65, 80, 100, 125, 150 | 100, 125, 150, 200, 250 | 59.0~125 | 2734~12272 |

Approximate weights for SV60 safety valves by port size (inlet/outlet) are shown in the table below (unit: kg):

Approximate weights for SV60 safety valves by port size (inlet/outlet) are shown in the table below (unit: kg):

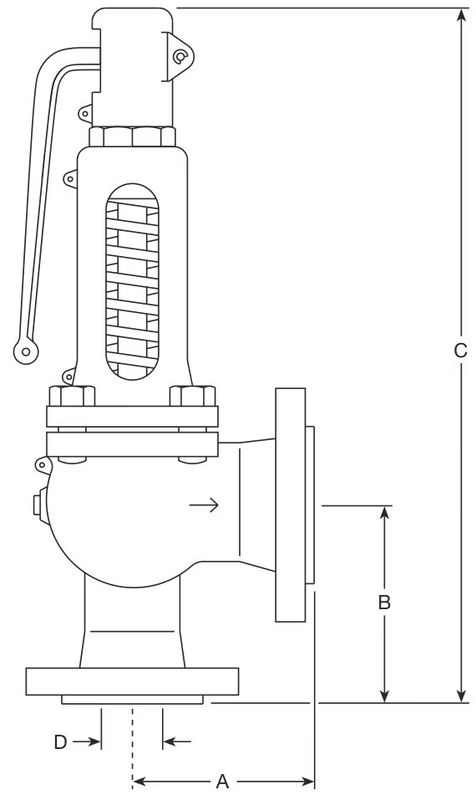

| Port Size (Inlet / Outlet) | Dimension A | B | C | Flow Ø D | Weight SV604 | SV607 |

|---|---|---|---|---|---|---|

| DN20 - DN32 | 85 | 95 | 385 | 17.0 | 10.5 | 10.5 |

| DN25 - DN40 | 100 | 105 | 435 | 23.8 | 12.5 | 11.5 |

| DN32 - DN50 | 110 | 115 | 450 | 30.6 | 16.0 | 15.0 |

| DN40 - DN65 | 115 | 140 | 520 | 38.0 | 18.0 | 18.0 |

| DN50 - DN80 | 120 | 150 | 535 | 50.1 | 20.0 | 22.0 |

| DN65 - DN100 | 140 | 170 | 710 | 59.0 | 40.0 | 38.0 |

| DN80 - DN125 | 160 | 195 | 790 | 73.0 | 56.0 | 53.0 |

| DN100 - DN150 | 180 | 220 | 835 | 91.0 | 77.0 | 75.0 |

| DN125 - DN200 | 200 | 250 | 1042 | 105.0 | 120.0 | 115.0 |

| DN150 - DN250 | 225 | 285 | 1165 | 125.0 | 190.0 | 180.0 |

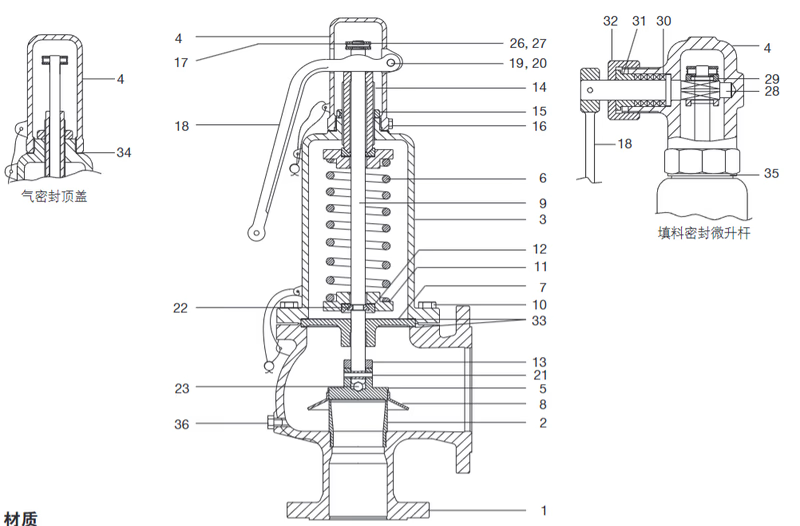

SV60 safety valve components strictly comply with industrial standards to ensure durability and suitability, as detailed in the table below:

| No. | Component Name | Material Specification | SV604/SV607 Adaptation Notes |

|---|---|---|---|

| 1 | Body | Carbon steel / Ductile iron | SV604: 1.0619 + N; SV607: GJS-400-18LT |

| 2 | Seat | Stainless steel | DN20~DN100: 1.4057; DN125~DN150: ANC2 |

| 3 | Bonnet | Carbon steel / Ductile iron | SV604: 1.0619 + N; SV607: GJS-400-18LT |

| 4 | Cap | Ductile iron | GJS-400-15 (common) |

| 5 | Disc | Hardened chrome vanadium alloy steel | Hardness 47-52HRC (Rockwell 'C'); DN20~DN100: 1.4021; DN125~DN150: CA15 |

| 6 | Spring (temperature > 230°C) | Tungsten alloy steel | For high-temperature applications, consult separately for configuration |

| 7 | Spindle guide | Ductile iron | GJS-400-15 (common) |

| 8 | Outer ring | Stainless steel | DN20~DN100: 1.4301; DN125~DN150: 1.4308 |

| 9 | Spindle | Stainless steel | 1.4021 (common) |

| 10 | Body bolts (4 pcs) | Steel | CK35 (common) |

| 11 | Spring washer | Carbon steel | C45E (matched to port size and set pressure) |

| 12 | Bearing ring (DN80~DN150 only) | Stainless steel | 1.4021 (for large port sizes only) |

| 13 | Spacer | Stainless steel | 1.4021 (common) |

| 14 | Spring adjusting screw | Stainless steel | 1.4021 (common) |

| 15 | Lock nut | Zinc-plated carbon steel | Common specification |

| 16 | Cap nut | Zinc-plated steel | Common specification |

| 17 | Locking ring | Zinc-plated carbon steel | Common specification |

| 18 | Lever (open type) | Ductile iron | GJS-400-15 (common) |

| 19 | Lever pin | Zinc-plated carbon steel | Common specification |

| 20 | Circlip | Spring steel | Common specification |

| 21 | Disc pin | Spring steel | DIN 7343, A304 (common) |

| 22 | Positioning ring | Stainless steel | 1.4021 (common) |

| 23 | Spindle ball | Stainless steel | Common specification |

| 26 | Locking ring pin | Zinc-plated carbon steel | Common specification |

| 27 | Locking ring circlip | Spring stainless steel | Common specification |

| 28 | Lever spindle | Stainless steel | ASTM A276 431 (common) |

| 29 | Cam | Carbon steel | Common specification |

| 30 | Packing | Graphite | Common sealing material |

| 31 | Packing gland | Stainless steel | ASTM A276 304 (common) |

| 32 | Gland nut | Carbon steel | Common specification |

| 33 | Spindle washer (2 pcs) | Reinforced graphite | Common sealing material |

| 34 | Blind cap gasket | Universal SA | Common sealing material |

| 35 | Lever chamber gasket | Universal SA | Common sealing material |

| 36 | Body drain plug | Steel | G½" (common specification) |

Note: The specific specifications of the spring washer (item 11) and bearing ring (item 12) are matched to the safety valve port size and set pressure. Actual configuration is subject to product delivery.

Calculated at 10% overpressure according to EN 1504126 standard, discharge capacities for different port sizes and set pressures are as follows (selected core range):

| Set Pressure (bar g) | DN20/32 | DN25/40 | DN32/50 | DN40/65 | DN50/80 | DN65/100 | DN80/125 | DN100/150 | DN125/200 | DN150/250 |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 129 | 269 | 401 | 525 | 875 | 1357 | 1889 | 3053 | 4299 | 6203 |

| 5.0 | 644 | 1374 | 2019 | 2783 | 4548 | 6970 | 9917 | 16347 | 22385 | 32165 |

| 10.0 | 1169 | 2493 | 3663 | 5049 | 8250 | 12644 | 17991 | 29655 | 40608 | 58352 |

| 20.0 | 2213 | 4721 | 6937 | 9562 | 15623 | 23944 | 34070 | 56158 | 76902 | - |

| 40.0 | - | - | - | - | - | - | - | - | - | - |

Calculated according to AD-MERKBLATT A2 and TRD 421 standards, core parameters are as follows (selected):

| Set Pressure (bar g) | DN50/80 | DN65/100 | DN80/125 | DN100/150 | DN150/250 |

|---|---|---|---|---|---|

| 0.5 | 472 | 1521 | 2115 | 4809 | 6955 |

| 10.0 | 6343 | - | - | - | - |

| 30.0 | - | 34789 | - | 81595 | - |

| 40.0 | 3559 | 38514 | - | - | - |

Calculated according to AD-MERKBLATT A2 and TRD 421 standards, core parameters are as follows (selected):

| Set Pressure (bar g) | DN20/32 | DN25/40 | DN32/50 | DN40/65 | DN50/80 | DN65/100 | DN80/125 | DN100/150 | DN125/200 | DN150/250 |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 4.6 | 8.9 | 14.9 | 22.9 | 39.8 | 55.0 | 84.1 | 130.8 | 174.1 | 246.7 |

| 10.0 | 19.6 | 37.9 | 63.1 | 97.2 | 168.8 | 233.2 | 357.0 | 554.8 | 738.6 | 1046.8 |

| 25.0 | 32.6 | 63.2 | 105.2 | 162.1 | 281.4 | 388.7 | 595.0 | 940.0 | - | - |

| 40.0 | 41.3 | 80.0 | 133.1 | 205.0 | 355.9 | - | - | - | - | - |

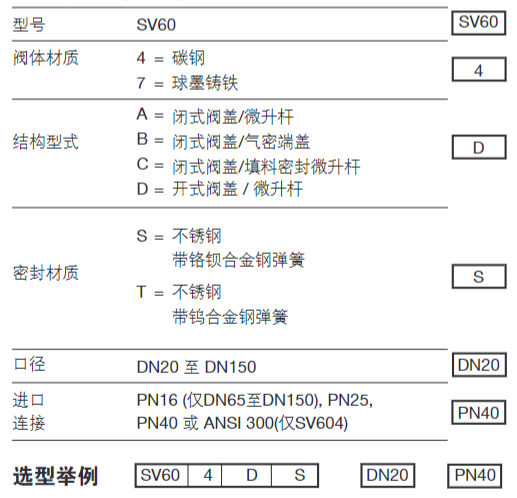

SV60 safety valve model codes consist of material, construction type, sealing material, port size and pressure rating, as shown in the following example:

| Selection Dimension | Available Options |

|---|---|

| Body material | 4=Carbon steel (SV604); 7=Ductile iron (SV607) |

| Construction type | A=Closed bonnet/lever; B=Closed bonnet/blind cap; C=Closed bonnet/packed lever; D=Open bonnet/lever |

| Sealing material | S=Stainless steel + chrome vanadium alloy steel spring; T=Stainless steel + tungsten alloy steel spring (high-temperature applications) |

| Inlet port size | DN20~DN150 (SV604); DN65~DN150 (SV607) |

| Pressure rating | PN16 (SV607 DN65~DN150 only); PN25 (SV607); PN40 (SV604); ANSI 300 (SV604 only) |

|

Explore similar products in our catalog