Spirax Sarco TD16/TD16F Thermodynamic Steam Trap, designed for low capacity steam mains and tracer lines, suitable for various applications within specific pressure, temperature and capacity ranges. Maximum working pressure 16 bar g, maximum working temperature 300°C, featuring stainless steel core components, available in both threaded and flanged connections, reliable construction, easy maintenance, effectively discharges condensate to ensure efficient steam system operation.

Spirax Sarco TD16/TD16F Thermodynamic Steam Trap is a high-efficiency steam system drainage device, primarily used for low capacity steam mains and tracer lines, also suitable for other industrial applications within its specified pressure, temperature and capacity ranges.

Key Advantages

| Model | Size | MPN | Connection |

|---|---|---|---|

| 1/2" TD16 | 1/2" | 1510015000 | BSP Threaded |

| 3/4" TD16 | 3/4" | 1510020000 | BSP Threaded |

| 1" TD16 | 1" | 1510025000 | BSP Threaded |

| Model | Size | MPN | Connection |

|---|---|---|---|

| DN15 TD16 | DN15 | 1510015002 | PN16 Flanged |

| DN20 TD16 | DN20 | 1510020002 | PN16 Flanged |

| DN25 TD16 | DN25 | 1510025002 | PN16 Flanged |

| Parameter | Specification |

|---|---|

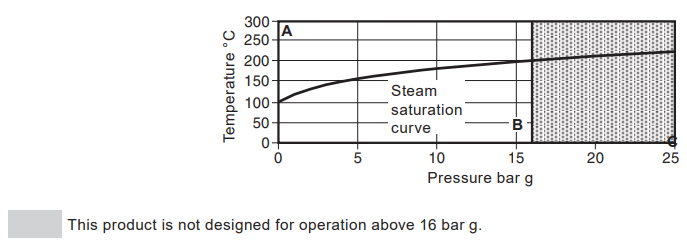

| PN Rating | PN 25 |

| Max. Allowable Pressure (PMA) | 25 bar g |

| Max. Allowable Temperature (TMA) | 300 °C |

| Max. Working Pressure (PMO) | 16 bar g |

| Max. Working Temperature (TMO) | 300 °C |

| Max. Cold Hydraulic Test Pressure | 38 bar g |

| Max. Working Backpressure | Not exceeding 80% of inlet pressure |

Backpressure Limitation

During operation, the maximum working backpressure must not exceed 80% of the inlet pressure, otherwise the steam trap will not close properly.

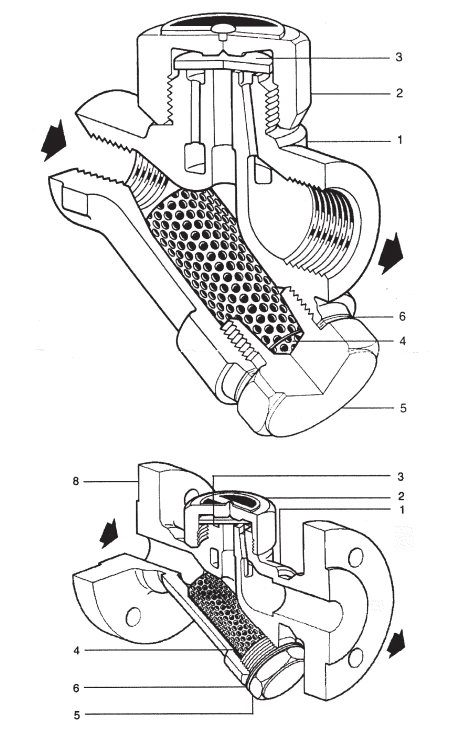

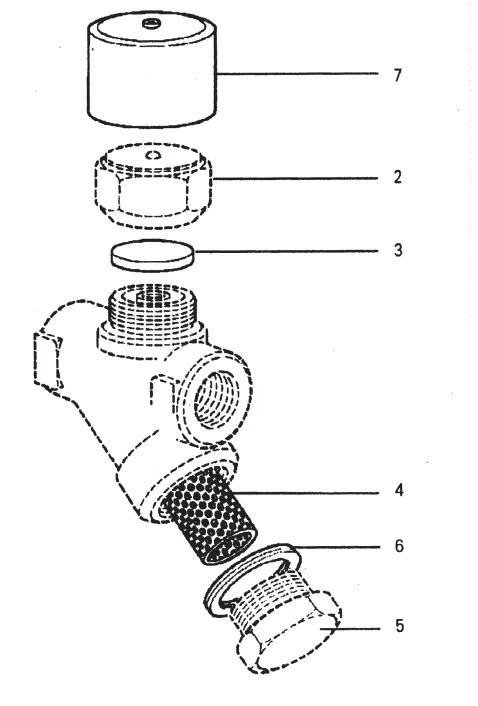

| Part No. | Part Name | Material Specification |

|---|---|---|

| 1 | Body | Stainless Steel (ASTM A743.Gr.CA40F) |

| 2 | Cap | Stainless Steel (AISI 416) |

| 3 | Disc | Stainless Steel (BS 1449 420 S45) |

| 4 | Strainer | Stainless Steel (BS 1449 304 S16) |

| 5 | Strainer Cap | Stainless Steel (AISI 416) |

| 6 | Strainer Cap Gasket | Stainless Steel (BS 1449 304 S16) |

| 7 | Insulating Hood (Optional) | Aluminium |

| 8 | Flange | Carbon Steel |

Note

The insulating hood is not shown in the product diagram and is an optional accessory.

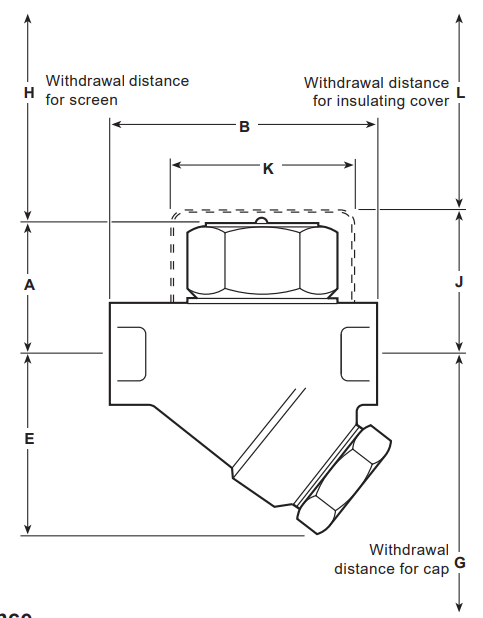

| Size | A (mm) | B (mm) | E (mm) | G (mm) | H (mm) | J (mm) | K (mm) | U (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 41 | 78 | 55 | 85 | 20 | 52 | 57 | 38 | 0.75 |

| 3/4" | 44 | 85 | 60 | 100 | 20 | 52 | 57 | 38 | 0.95 |

| 1" | 48 | 95 | 65 | 100 | 20 | 58 | 57 | 38 | 1.50 |

| Size | A (mm) | B1 (mm) | E (mm) | G (mm) | H (mm) | J (mm) | K (mm) | U (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| DN15 | 41 | 150 | 55 | 85 | 20 | 52 | 57 | 38 | 1.95 |

| DN20 | 44 | 150 | 60 | 100 | 20 | 52 | 57 | 38 | 2.65 |

| DN25 | 48 | 160 | 65 | 100 | 20 | 58 | 57 | 38 | 3.90 |

Dimension Notes

| Accessory | Function |

|---|---|

| Insulating Hood | Prevents excessive cycling caused by heat loss in cold, wet or windy environments, improving operational stability |

| Integral Blowdown Valve | Installed by drilling a 1/4" BSP tapped hole in the strainer cap, convenient for system blowdown maintenance (refer to TI-P153-01) |

Installation Instructions

Before performing any maintenance work, ensure:

| Part | Size | Tightening Torque (Nm) |

|---|---|---|

| Cap (Part 2) | 1/2", DN15 | 135 - 150 |

| Cap (Part 2) | 3/4", DN20 | 135 - 150 |

| Cap (Part 2) | 1", DN25 | 135 - 150 |

| Strainer Cap (Part 5) | All sizes | 170 - 190 |

| Spare Part Name | Part No. | Notes |

|---|---|---|

| Disc | 3 | Suitable for all models |

| Strainer and Gasket | 4, 6 | Supplied as a set |

| Strainer Cap Gasket | 6 | Supplied separately |

| Insulating Hood | 7 | Optional accessory |

Spare Parts Ordering

When ordering spare parts, clearly specify the spare part name, corresponding steam trap model and size.

Example: Strainer and gasket for 1/2" TD16 Thermodynamic Steam Trap

Ordering Requirements

When ordering, provide the full product description, clearly specifying the steam trap model, size, connection type and other key configurations. If optional accessories are required, specify in the order.

Important Notes

Explore similar products in our catalog